Overview

This case study explores how Riverfield Farm in Golden Bay improved cow flow, reduced lameness, and created a safer, more efficient stand-off area by installing NumatAGRI rubber matting across their yard, races, and milking shed. The upgrade delivered long-term gains in comfort, labour savings, and pasture protection.

The Challenge: Tackling Lameness and Winter Wear

Riverfield Farm was dealing with the kind of issues many dairy operations face. Rising lameness, sore-footed cows, and the ongoing hassle of washing down hard concrete yards. During winter, things got even tougher.

The team needed a solution that could improve animal welfare, reduce wear, and make the whole operation run smoother through the season.

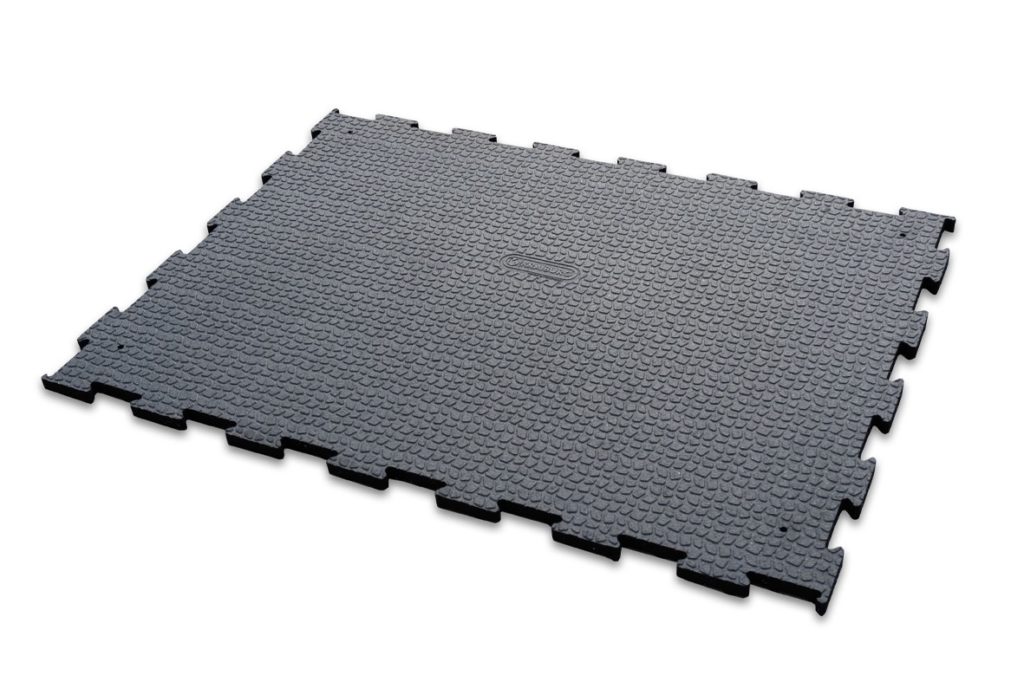

The Solution: Rubber Mats That Require No Maintenance

They installed rubber matting across the key high-pressure areas. The main dairy yard, exit and vet races, the cups-on area inside the shed, and Zig Zag matting in the lead-in race to reduce the number of stones being carried in.

Each section was chosen to improve comfort, reduce injury, or cut down on day-to-day maintenance. The mats came with a 10-year warranty and have required no upkeep so far. Just a rule to keep vehicles off them. Since going in, they’ve become an integral part of how the farm manages cow flow and stand-off time.

“We’re using the yard more, saving time, saving costs, and the cows are more comfortable. It’s a success on all fronts.”

Hayden Pomeroy, Riverfield Farm

The Results: Fewer Lame Cows, Better Flow, Happier Staff

Lameness has dropped across the herd, and the cases that do come through are far less severe than they were in previous seasons. Cows move more freely through the yard and don’t hesitate at the usual high-slip spots.

With the improved surface, the team has also been able to keep cows in the yard longer without worrying about hoof damage. That’s made day-to-day operations easier during peak pressure times. Inside the shed, staff have noticed a major difference too. The cushioned cups-on area reduces leg fatigue and makes long milkings far more manageable.

• Lameness reduced both in numbers and severity

• Cow flow has improved, especially through tricky areas

• Staff are more comfortable during long milkings

Unexpected Benefits: Easier Wash-Down, Smarter Effluent Use

The new surface has also led to better water use. Washing down is faster and requires less water. The yard now functions as a stand-off area year-round and was used sometimes through winter for the springer mob. That’s helped keep paddocks intact and given cows a dry, safe place to calve.

To make the most of that added use, the team also upgraded their effluent system. They’re now spreading by K-lines and cutting back on fertiliser costs.

The Takeaway: A Long-Term Fix That’s Already Paying Off

Rubber matting has changed how Riverfield Farm runs its yard. Boosted cow comfort, more time saved and keep the infrastructure protected. With lameness down, happier staff, and less maintenance needed, it’s proven to be a smart investment on all fronts.

Every farm’s different.

Let’s find what works for yours.

Further Case Studies

View AllFurther Case Studies

Lameness Cut by 67% at GD Prout Farm

Paeroa, Waikato

Prior to installing rubber matting, the farm was experiencing significant issues around lameness within the herd. This was not only causing a loss in milk production but an increase in veterinary costs.

Further Case Studies

Happy Cows Making More Milk for Max Varney

Piopio, Waikato

After dealing with cows slipping Max made the call to install some rubber matting to create a more comfortable and non-slip surface for his animals.

Further Case Studies

95% Reduction in Slipping & Hoof Problems at McLaggan Farm

Taupiri, Waikato

Lance McLaggan contacted NumatAGRI for rubber matting after witnessing cows beginning to slip coming in and out of the shed.

Further Case Studies

95% Drop in Lameness at Isla Bank Dairy Farm

Isla Bank, Southland

Isla Bank dairy farm installed rubber matting for a massive 95% drop in lameness, better cow flow, and increased productivity.