Dairy Conversion in Practice: Composting Barn Open Day

More than 70 farmers and agri pros turned up to the Willesden open day. They walked the full 185 m...

ReadThe Gist: Willesden Farms converted 300ha in Kaituna Valley to dairy, milking 800 cows with a composting barn at its core. This slashes the environmental footprint by 46% while protecting pastures from winter pugging and summer heat stress. ROI hits in five years with the 50+ year structure delivering long-term profits. A no-brainer for farming smarter on a land that has imperfect drainage.

In Banks Peninsula’s Kaituna Valley, Willesden Farms has turned 300 hectares into a dairy operation, milking 700 cows this season. The pivot hinges on a new composting barn that slashes the farm’s environmental footprint by 46%. Owner Brent Thomas calls it a formula for viability as milk payouts climb, while general manager Matt Iremonger sees it as a practical fix for tough land.

Before the barn, wet winters turned paddocks into mud traps, with cows slipping and pastures taking a beating. Now, they stay off the land during rain or heatwaves, preserving soil for regrowth. Summers once saw production dip from stressed herds—now shade keeps them steady. This shift protects pasture and boosts output.

Matt Iremonger didn’t rush into this. He researched composting barns across New Zealand, Australia, and the US, visiting sites in Waikato, Taranaki, Southland, the West Coast, and Canterbury. “We looked at how these systems were able to augment our pastoral system,” he says. The goal was to squeeze more value from wet winter land without ditching pasture.

The barn serves dual purposes: wintering 550 – 650 non-milking cows in June and July, and sheltering up to 800 during bad weather. “It’s designed for the full eight hundred during adverse weather at any time of the year,” Matt notes. That covers spring rains, autumn mud, or summer heat for shade.

Extras like clearlight roofing, solar panels, and electric doors at the southern end add resilience. The barn captures all effluent, ditching the need for ponds.

Get real numbers, not guesses.

We’ll show you the smartest way to build your composting barn: cost-efficient, practical, and built around your farm.

The frame uses NuSpan laminated timber —Prolam— sourced from sustainable NZ plantations. This eco-friendly alternative to steel-framed barns is up to 20% more cost-effective than traditional builds. It handles moisture in effluent-heavy settings without corroding.

Matt praises the choice. “We were really attracted to it because it was cost efficient, highly durable,” he says. The construction team found it easy to work with, delivering a warmer, softer space that fits the farm’s vibe.

If you want the full rundown on how laminated timber performs in farm buildings, the Prolam Structural Timber Guide covers everything you need to know. It’s a solid resource for understanding strength, durability, and why laminated timber stacks up so well in New Zealand conditions.

Built for 50+ years, the barn is a long-term play. “We’ve modelled it as a 50 year piece of infrastructure but there’s no reason that it wouldn’t last significantly longer,” Matt says. Return on investment lands in five years, with profits rolling in after from higher productivity and lower costs generating savings on off-farm wintering.

No more trucking herds off-site. “We’ve got the ability over a long period of time to get a return,” Matt adds. Better pasture efficiency lifts stocking rates without harm.

Before, wet weather left cows cold and stressed on muddy paddocks. Now, the compost beds keep them dry and comfortable. Herds rest easy, even in storms or heatwaves.“The barns unlock the ability for us to have a better financial return… but also an animal welfare perspective,” Matt states. Herds stay warm and dry, even in storms.

Staff feel it too. Last month’s wet night, saw heavy rain—proved the point. “It just takes a lot of stress away from the farm operators, but also from the animals themselves,” Matt recalls. Cows were safe, pastures untouched.

The barn cuts methane and nitrate outputs, key culprits in dairy emissions. NZ dairy faces regulations aiming for a 30% emissions cut by 2030—this aligns with that push. By keeping cows indoors during wet spells, nitrogen leaching drops from 15-20 kg/ha annually to near zero, per industry benchmarks.

Matt links it to sustainability. “It protects our nutrients and it looks after the cows,” he explains. Monitoring during consenting shows net gains, putting Willesden ahead of the curve.

This conversion shows how to farm smarter in NZ’s wild weather. It protects pasture, meets emissions rules, and lifts welfare—all with ROI in five years. Willesden’s model could guide others on similar land.

Opportunities abound for growth. High milk prices fuel conversions, with Canterbury seeing consents surge fourfold since last year. Exports to markets like China drive demand, while NZ’s low-cost production edge keeps farms competitive globally. Milk output is set to rise, with herd numbers increasing through reduced culling and new setups.

The upsides pull farmers in. Dairy offers higher returns than dryland grazing on similar land, with asset values climbing in areas like Southland. Globally competitive costs keep it viable. Tech like composting barns tips the balance: they cut nitrate leaching by up to 50%, slash methane via better feed efficiency, and enhance sustainability for long-term business resilience.

Kaimoo / Willesden’s case fits the pattern. On Banks Peninsula’s wet slopes, the conversion swaps cropping for year-round grass, avoiding exposed soil and boosting fertility. The barn’s 46% footprint cut—via captured effluent and indoor shelter—mirrors sector-wide moves to meet 2030 emissions targets without slashing output. Matt Iremonger’s research echoes broader farmer caution: conversions work when paired with systems that protect assets long-term, turning compliance pressures into straightforward advantages.

Get a quick quote and discuss customisation options.

More than 70 farmers and agri pros turned up to the Willesden open day. They walked the full 185 m...

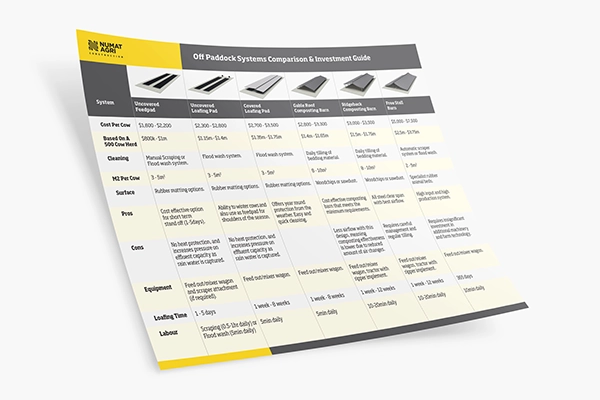

ReadThis comprehensive guide delves into the various off-paddock facility options, their benefits, challenges, and costs, providing you with the necessary...

ReadOver 70 farmers turned up to walk through Willesden’s 31 m × 185 m composting barn, the heart of a...

ReadWillesden barn Open Day - December 2nd. Walk the first New Zealand laminated timber barn. Get insights on 1,000 cow...

ReadQuickly understand and compare all major off-paddock systems with our comprehensive, one-page guide. It covers:

Cut through the noise and get the clear insights you need to make an informed choice.