Dairy Conversion: Willesden Farms Composting Barn

Willesden Farms completed a dairy conversion on 300 hectares, now...

Read MoreA composting barn is an off-paddock housing solution where cows rest on a composting bed under a covered roof. The barn’s design promotes cow comfort and health by providing a warm, dry, and well-ventilated environment. Composting barns are increasingly popular for their environmental benefits and cow welfare considerations.

Composting barns have been proven to be one of the most comfortable surfaces for cows, with many studies showing lying times of between 10-12 hours per day, which when compared against other alternatives is significantly higher. This directly impacts milk production per cow, because blood flow to the udder increases 30-40% when lying down.

The simplicity of a composting barn, allows all manure created in the barn to be captured and stored without the need for effluent holding facilities like sumps, weeping walls etc. This in turn means money is saved and the farmer does not have to invest in larger effluent ponds, like they would with other systems.

When managed correctly, cows in composting barns are generally cleaner and have less chance of going lame because of how soft the surface is when compared to other systems. This however is dependent on the walking distance and track materials cows are exposed to.

Get real numbers, not guesses.

We’ll show you the smartest way to build your composting barn: cost-efficient, practical, and built around your farm.

Research into the local availability and cost of woodchip or similar is a crucial part of planning for a composting barn. The quality of the material and cost can vary significantly depending upon region.

One of the most overlooked aspects of composting barn projects is the importance of choosing a site that compliments the current farming operation and any future developments (calf sheds, access to feed bunkers etc.)

The proposed site should be checked for nearness to property boundaries, housing, and waterways. The gradient of the site is important as the cost of leveling the site can either make or break a project.

Thought should be given to the required daily management of the barn and equipment needed for this. In most cases an additional tractor, ripper attachment, and labour are required to allow for efficient and effective management. Regular monitoring of the bedding pack is crucial to ensure the temperature doesn’t drop below 50 degrees and the moisture content doesn’t exceed 70%. Staff should be trained to monitor the compost pack.

Willesden Farms completed a dairy conversion on 300 hectares, now...

Read MoreWillesden Farms' composting barn slashes environmental footprint by 46%. Featured...

Read MoreUnderstand the cost of building a composting barn, what drives...

Read MoreWillesden’s composting barn is almost done. 550-cow capacity, 740m of...

Read MoreWith a NuSpan Timber Barn, you can protect your pasture...

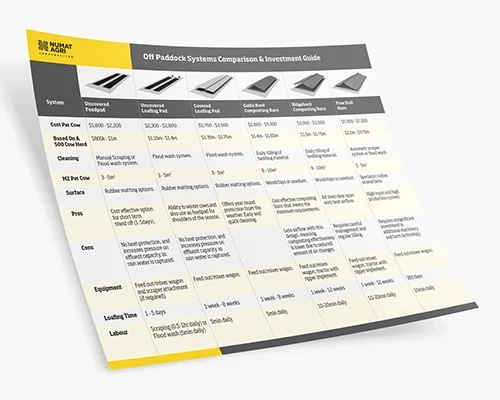

Read MoreQuickly understand and compare all major off-paddock systems with our comprehensive, one-page guide. It covers:

Cut through the noise and get the clear insights you need to make an informed choice.

Entegra’s Ridgeback™ Dairy Sheds, exclusively supplied by NumatAGRI in New Zealand, showcase a patented climate-controlled design that ensures 20% higher air exchanges per hour compared to traditional dairy sheds. Leveraging over 37 years of industry experience, these sheds optimize milk production and ROI.

Curved roof to maximise natural ventilation, thereby minimising the chance of heat stress and the growth of bad bacteria.

Flexibility in the layout of the shelter to maximise efficiency in feed and water delivery.

Hot-dipped galvanised trusses come as a standard option for durability and the ultimate steel finish.

Curved roof of the Ridgeback™ provides great aesthetics and gives a unique looking and state-of-the art barn.

The cost of constructing a Ridgeback™ Shelter varies based on several factors, including size, flooring choices, and additional features. Typically, the cost ranges from $1,600 to $2,500 per cow. Factors influencing the cost include:

Exclusive access to patented designs for self ventilating roof structures

Exclusive access to a patented tapered gutter system

Get a quick quote and discuss customisation options.